less info

less info

1. The liquid is assumed to be water (viscosity= 1cSt). Pipes or tubes are smooth (roughness = 0.0018") for steel and 0.00006" for PVC, steel has been assumed here.

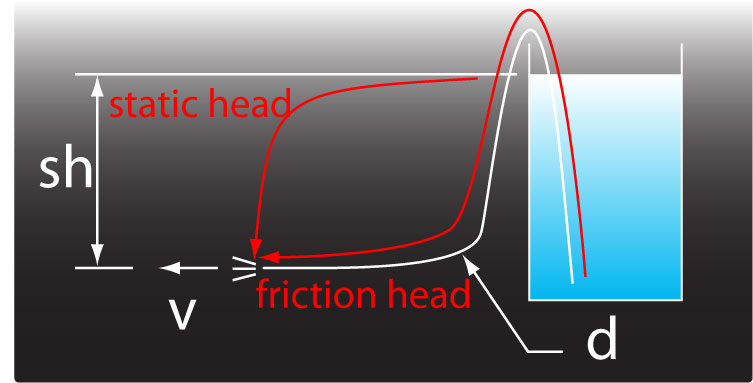

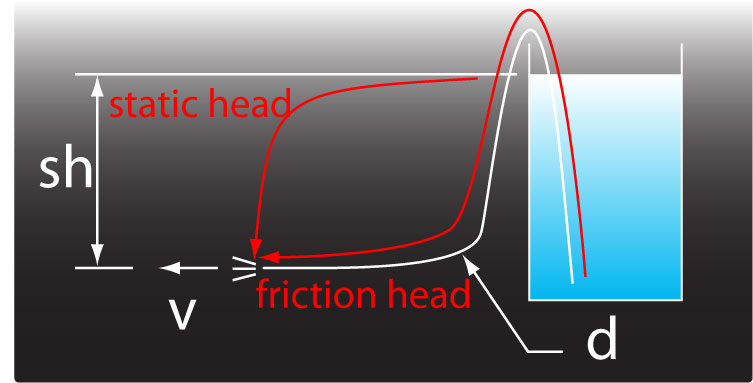

2. The diameter d is the pipe inside diameter.

3. The velocity at the end of the tube will depend on the friction loss and the static head. The friction loss calculation is done

using the Swamee-Jain formula. The Swamee-Jian formula provides the friction and contains the Reynolds number

which contains the velocity variable. The formula for the system is v2/2g = sh - hf. One side of the equation has the v variable and the other also a v variable

but it is not possible to isolate v on one side of the equation, therefore we need to use an iteration technique. Which consist of assuming a solution for v, putting that

value into the equation and seeing how close each side gets to being equal, and repeating this exercise by changing v slowly until we get equality. This can be a long

process if you don't have a technique to get to the answer quickly, that's why we need an iteration tevhnique and Newton-Raphson is one of the best and used here.

Here is an example of the Newton-Raphson  used to solve for the friction factor in the Colebrook equation.

used to solve for the friction factor in the Colebrook equation.

4. The calculator provides the flow and velocity for a given tank level. The flow will decrease as the tank empties.

5. Some thoughts on head and friction and how they are related .

.

6. Here are the formulas  used for this calculation.

used for this calculation.

7. As I finished this app I realized that it applies equally well to a water turbine intake except there is no nozzle,

see these 2 documents on micro-hydro no.1 and no. 2.

8. You can test these formulas with this Excel workbook  .

.

The formulas are complex, there are several possibilites for error: in the derivation, the transcription, a wrong parenthese here or there.

And finally once they appear to be working they can give a reasonable result and still be wrong.

The biggest indicator that the formula has an error even though the result seems correct is the value of the residue RES. The RES is the value by which you

reduce the variable to be determined at every iteration. The value for RES can be set as low as one wants, Newton-Raphson converges very quickly and rarely

does it take more than 5-6 iterations. A confirmation that everything is working properly is when you do the calculation manually or with the spreadsheet the

RES value approaches its final low value from the negative and positive side.

To remove all doubt and put this to rest I did an experiment to test the results.

I used an 0.25" ID tube, 10 ft long and a static head of 4.8". I measured the flow rate by timing the duration of filling a 500 mL measuring cup.

The results are within 1 to 5% of the prediction of the app. Not bad, I think!

You can easily make your own tests and you don't even need a hole and a tube fitting in the side of the bucket, just set it up as a siphon.

Keep in mind that this is not advisable for a real system because inevitably air will get into the tube, rise to the top of the siphon loop and stop flow.

.

.

9. This app is intended to be used for educational purposes, the author takes no responsibility for the use of these results.

J. Chaurette June 6, 2018

Copyright 2019, PumpFundamentals.com

less info

less info used to solve for the friction factor in the Colebrook equation.

used to solve for the friction factor in the Colebrook equation.

.

.

used for this calculation.

used for this calculation.

.

.

.

.